Advancing Machine Tool Technology and Automation #

Jiuh-Yeh Precision Machinery is dedicated to enhancing manufacturing efficiency and precision through continuous research and development. Our R&D efforts focus on integrating advanced monitoring, automation, and compensation technologies into our machine tools, ensuring optimal performance and reliability for our customers.

Real-Time Monitoring System #

Our Real-Time Monitoring System is designed to oversee multiple machines simultaneously. Compatible with Fanuc, Mitsubishi, and Syntec systems, it aggregates machine data for centralized display and management. The system features an internet-enabled edition and a multi-machine monitoring program, allowing seamless data transfer to cloud platforms. Users can access comprehensive machine information remotely via the internet or mobile devices.

Automated Guided Vehicle (AGV) and Robotic Integration #

Our automation system incorporates Automated Guided Vehicles (AGVs) and robotic arms to streamline the removal of workpieces. The AGV system can connect with multiple machines, enabling coordinated workpiece handling. Key benefits include reduced labor requirements, optimized factory space utilization, and enhanced operational efficiency.

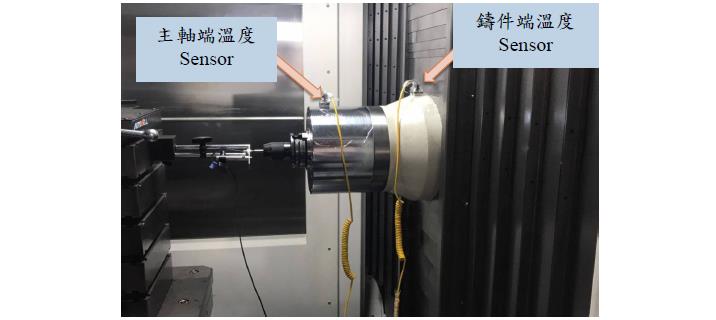

Spindle Thermal Displacement Compensation #

During extended operation, spindle heat can cause thermal elongation, affecting machining accuracy. Our Spindle Thermal Displacement Compensation technology addresses this by compensating for thermal growth, thereby maintaining high machining precision.

Multi-Axis Error Measurement System #

In collaboration with National Formosa University, we have developed the IBS R-TEST and a five-axis multi-machine error measurement system. This technology enables simultaneous multi-axis compensation, significantly improving machine accuracy. The R-TEST system analyzes positional errors and applies corrections directly to the controller, meeting stringent customer accuracy requirements. Key functions include B-axis compensation, both active and passive, and comprehensive multi-axis compensation analysis.